Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

Plasma, often referred to as the fourth state of matter, is an electrically conductive mixture of charged particles (ions and free electrons) and neutral atoms or molecules. Unlike solids, liquids, or gases, plasma is defined by the presence of these charged components and its overall quasi-neutrality (near balance of positive and negative charges). Artificial plasma, in particular, is plasma generated in controlled environments, as opposed to naturally occurring plasma like that found in stars or lightning. This ability to generate plasma in controlled settings underpins numerous scientific breakthroughs and industrial applications, such as materials processing, semiconductor manufacturing, nuclear fusion research, space propulsion, environmental remediation, biotechnology, medicine, and food sterilization.

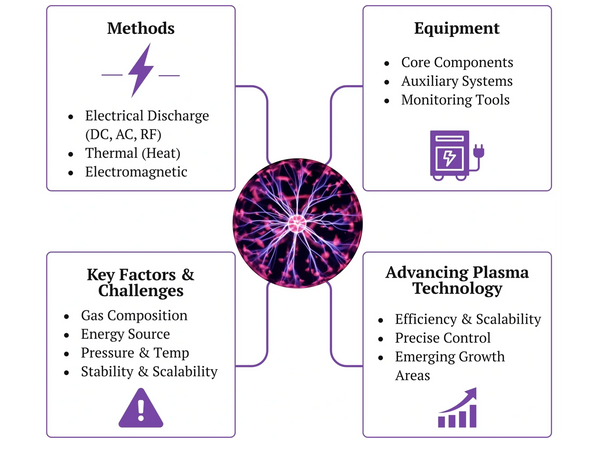

The generation of artificial plasma (hot, warm, and cold) is significant as it allows for precise control and engineering of plasma's properties—such as density, temperature, and reactivity—making it an indispensable tool for cutting-edge technologies. The methods used, along with factors such as design, materials, and energy inputs, directly influence the type of plasma produced, ensuring it meets the specific demands of various applications. An in-depth understanding of plasma generation methods and influencing factors is, therefore, crucial to unlocking its full potential across disciplines.

Methods of Generating Artificial Plasma

Artificial plasma is generated by applying energy to a neutral gas, causing its particles to become ionized. The choice of generation method is critical, as it directly determines the plasma's characteristics and type. High-energy methods produce thermal (or "hot") plasma, where all particles reach extremely high temperatures, suitable for applications such as plasma arc welding and nuclear fusion. In contrast, other methods generate non-thermal plasma, which maintains a lower overall gas temperature even while its electrons are highly energetic. This category encompasses both warm and cold plasmas, which are crucial for temperature-sensitive processes such as biomedical sterilization and surface modification. The most common plasma generation methods utilize various energy sources, including electrical discharge techniques such as direct current (DC), alternating current (AC), radio frequency (RF), and microwaves, each capable of producing plasma with specific properties engineered for its intended use.

Equipment Used to Generate Plasma

The generation and control of plasma involve the use of specialized equipment and supporting infrastructure designed to meet the demanding requirements of both experimental and industrial applications. Recent advancements in automation, material durability, and non-contact technologies have significantly improved scalability and efficiency, facilitating smoother transitions from laboratory-scale experiments to large-scale industrial processes. The equipment and infrastructure can generally be categorized into three key groups: core components (such as plasma reactors, power supplies, electrodes, and vacuum chambers), auxiliary systems (including cooling mechanisms and contamination-prevention devices), and monitoring tools (precision instruments for measuring key parameters such as temperature, density, and plasma stability). These elements work together to ensure reliable plasma generation and control across a range of operating conditions.

Key Factors and Challenges in Plasma Generation

The generation and practical application of artificial plasma rely on several critical factors that directly influence its efficiency and behavior. These influencing factors include gas composition, pressure, temperature, and the materials and configurations of electrodes—each of which is essential in determining the ionization process, reactivity, and overall plasma performance. Additionally, the energy source and frequency (e.g., radio frequency or microwave methods) are crucial for precisely controlling plasma characteristics, allowing for engineered solutions across various industries, from manufacturing to biotechnology.

However, significant challenges continue to slow the broader adoption of plasma technologies. Maintaining stability under fluctuating pressures, improving energy efficiency, and scaling systems for industrial applications present ongoing obstacles. Moreover, the extreme conditions associated with plasma operations impose rigorous durability demands on equipment, necessitating continual advancements in material science to ensure reliability and cost-effectiveness.

Advancing Plasma Technology

The future of plasma technology is being driven by technological advancements that aim to enhance efficiency, expand industrial scalability, and achieve precise control. Emerging growth areas include the development of adaptive power supplies, the integration of machine learning algorithms, the use of advanced diagnostics and simulation tools, and the creation of hybrid plasma systems, all of which are reshaping the field and expanding its potential across various sectors.

Artificial plasma generation is a transformative field of science and technology, offering engineered solutions to diverse challenges in industry, medicine, energy, and agriculture. By allowing precise control over plasma's physical and chemical properties through various generation methods, researchers and engineers can optimize plasma for specific applications, from cutting-edge semiconductor fabrication to sustainable energy research.

As new advancements in materials, computational modeling, and plasma generation technologies emerge, the role of plasma in shaping the future of key industries will only grow. By addressing challenges such as energy efficiency, scalability, and durability, researchers can unlock even greater potential for this remarkable state of matter. Plasma generation continues to exemplify the integration of scientific innovation and practical application, bridging foundational research with real-world impact.

Plasma generation methods are categorized based on the type of energy used to ionize a gas. These methods—ranging from electrical discharge and thermal heating to electromagnetic waves, shockwave-induced mechanisms, explosive energy, and fusion-specific techniques—utilize distinct principles to create plasmas with engineered characteristics. Each method leverages unique energy delivery systems to generate plasmas of varying densities, temperatures, and properties, making them suitable for diverse applications across industrial, scientific, and technological fields. A deeper understanding of these mechanisms enables the optimized use of plasma in cutting-edge endeavors, ranging from medical sterilization to nuclear fusion research.

The methods of plasma generation offer a wide spectrum of possibilities, each engineered to meet specific application needs. Electrical discharge methods provide versatility for a variety of industrial and scientific applications, from low-temperature plasma for sterilization to high-temperature plasma for material processing. Thermal methods offer the high energy and density required for fields such as welding and fusion research. Electromagnetic techniques enable the generation of contamination-free plasma, which is crucial for precision applications such as semiconductor manufacturing. Meanwhile, shockwave, explosive, and fusion-specific methods meet unique challenges in research and advanced energy systems. Understanding the strengths and challenges of each approach is crucial for aligning plasma properties with application demands, enabling innovation and advancing technologies across various disciplines.

Electrical discharge methods are commonly used to generate artificial plasma. These methods apply an electric field to a gas, accelerating free and bound electrons. When these energized electrons collide with neutral gas atoms, they impart sufficient energy to strip electrons away, leading to ionization and the formation of plasma. The na

Electrical discharge methods are commonly used to generate artificial plasma. These methods apply an electric field to a gas, accelerating free and bound electrons. When these energized electrons collide with neutral gas atoms, they impart sufficient energy to strip electrons away, leading to ionization and the formation of plasma. The nature of the resulting plasma—whether it is classified as cold, warm, or hot—depends on the energy input and the resulting temperature of the electrons and ions. Notable examples of electrical discharge techniques include:

Direct Current (DC) Discharge: This method involves continuously applying an electric current to generate plasma. DC discharge is often used in applications requiring stable and long-duration plasma, such as neon lights, which create vibrant colors through the excitation of neon gas. Other uses include various sputtering processes, where materials are deposited onto surfaces.

Alternating Current (AC) Discharge: AC discharge operates by applying an alternating electric field to the gas, producing an oscillating current that can ionize the gas. This method is common in fluorescent lamps, where the periodic current generates light through gas ionization. The alternating nature of the current also helps maintain the gas's ionization over time.

Radio Frequency (RF) Discharge: RF discharge uses high-frequency alternating currents to generate plasma. This method is frequently used in plasma etching and deposition processes during the fabrication of semiconductors. The RF field can maintain the acceleration of electrons and enhance the ionization process, resulting in higher-density plasma, which is essential for creating fine features in semiconductor materials.

Thermal plasma generation involves heating gas to extremely high temperatures, typically thousands of degrees Kelvin, resulting in ionization through thermal collisions. In this process, the gas molecules gain kinetic energy from the heat source, enabling them to collide with one another and eject electrons, which results in the formation

Thermal plasma generation involves heating gas to extremely high temperatures, typically thousands of degrees Kelvin, resulting in ionization through thermal collisions. In this process, the gas molecules gain kinetic energy from the heat source, enabling them to collide with one another and eject electrons, which results in the formation of ions. This results in a state of thermal equilibrium, where electrons and ions achieve a balance in energy distribution. Due to the extreme temperatures, thermal plasmas are generally classified as hot plasmas, characterized by high density and energy. Examples of thermal plasma generation methods include the following:

Arc Thermal Plasma: This method generates plasma through an electrical arc established between two electrodes. The arc provides an intense, localized heat source, reaching temperatures exceeding 30,000 K. The high energy from the arc ionizes the gas, creating plasma.

Inductively Coupled Thermal Plasma (ICTP): In this method, an alternating magnetic field induces a current in a gas, generating heat and resulting in ionization. The electromagnetic field is generated by an inductive coil wrapped around a quartz chamber that contains the gas. This technique enables the generation of extremely high-density plasma with excellent uniformity and stability.

These techniques use oscillating electromagnetic fields to ionize gases, enabling the generation and maintenance of plasma without direct contact with electrodes. This characteristic is particularly advantageous in various applications, as it helps to avoid contamination that can occur with electrode contact. Moreover, these methods tend

These techniques use oscillating electromagnetic fields to ionize gases, enabling the generation and maintenance of plasma without direct contact with electrodes. This characteristic is particularly advantageous in various applications, as it helps to avoid contamination that can occur with electrode contact. Moreover, these methods tend to produce high-density and uniform plasmas, which are highly advantageous for a range of industrial applications, including:

Microwave Discharge: This method uses microwave radiation to generate plasma. By applying high-frequency electromagnetic waves (typically in the 2.45 GHz range), microwave discharge efficiently ionizes gases and creates plasma. Microwave discharge often produces cold plasmas—defined by low gas temperatures (generally < 40°C)—which are useful for surface treatments, sterilization, and material modification without causing thermal damage to sensitive substrates.

Inductively Coupled Plasma (ICP): ICP is a widely used technique that uses an inductive coil to generate a high-frequency alternating magnetic field. This magnetic field induces an electric current within the gas, leading to ionization. The resulting plasma is known for its uniformity and stability. The ambient gas in ICP systems can vary, allowing for the generation of warm plasma and providing flexibility depending on the specific application needs.

Electron Cyclotron Resonance (ECR): ECR plasma generation relies on the interaction between charged particles and a magnetic field, which allows electrons to gain energy from microwave radiation. This method is particularly effective in producing high-density plasmas with excellent control over their properties.

Shockwave and explosive methods are dynamic techniques for generating plasma that use rapid energy transfer through shock waves or explosive reactions. These methods are characterized by creating high-temperature plasmas in extremely short timeframes, often in the order of microseconds. The intense pressure and energy released during thes

Shockwave and explosive methods are dynamic techniques for generating plasma that use rapid energy transfer through shock waves or explosive reactions. These methods are characterized by creating high-temperature plasmas in extremely short timeframes, often in the order of microseconds. The intense pressure and energy released during these events can lead to thermal ionization, producing plasma with unique properties that can be used for various scientific and industrial applications.

Strong Shock Wave Ionization: This method involves generating a powerful shock wave, typically through the detonation of an explosive material. The shock wave propagates through a medium, creating extreme conditions that lead to the ionization of gas. This method often produces hot plasma due to the high temperatures achieved through strong shock wave ionization, which exceed the thresholds for hot plasma, reaching temperatures of thousands of degrees Kelvin.

Weak Shock Wave Ionization: This method involves lower-intensity shock waves that can still generate plasma but with less extreme conditions compared to strong shock wave ionization. These methods can be designed to maintain control over the plasma characteristics. While the plasma generated by weak shock wave ionization is still considered hot plasma, the energy levels are moderated compared to strong shock wave methods, allowing for a more controlled exploration of fusion dynamics.

These plasma generation techniques are designed to achieve the precise conditions required for nuclear fusion. These methods employ advanced technological approaches, such as magnetic or inertial confinement, to heat, stabilize, and control plasma, aiming to replicate the extreme temperatures and pressures found in stars. These methods ca

These plasma generation techniques are designed to achieve the precise conditions required for nuclear fusion. These methods employ advanced technological approaches, such as magnetic or inertial confinement, to heat, stabilize, and control plasma, aiming to replicate the extreme temperatures and pressures found in stars. These methods can achieve hot plasma conditions, often exceeding temperatures of over 150 million degrees Kelvin, which is essential for facilitating fusion reactions. Understanding these methods is critical for advancing fusion energy research, which holds the potential for a cleaner and limitless power source.

Each category encompasses several techniques that may combine aspects from different methods, often resulting in substantial variations in plasma properties. Understanding these categories helps select the most appropriate method for specific industrial and scientific applications, ultimately advancing artificial plasma technology.

Generating artificial plasma, the fourth state of matter, involves highly specialized equipment designed to create, sustain, and control ionized gases under different temperature and pressure conditions. The type of plasma generated—whether hot, warm, or cold—and its intended applications guide the selection of equipment and system configurations. Plasma can be generated in environments ranging from low-pressure vacuum chambers to atmospheric or high-pressure conditions, with each scenario requiring meticulous design and customization of tools. To ensure precise control over plasma properties, such as density, temperature, chemical composition, and spatial uniformity, a detailed understanding of the critical equipment involved is fundamental.

At the core of most plasma systems are components like power supplies, plasma chambers, and electrodes, which constitute the essential building blocks of the technology. In addition to these, various specialized tools enhance the system's functionality, including vacuum systems for maintaining low-pressure conditions, gas delivery setups for regulating the process environment, and microwave or radio frequency (RF) sources for effective plasma excitation and control. Auxiliary components, such as cooling systems, diagnostic tools, and safety equipment, are essential for ensuring stable, efficient, and safe plasma operation while addressing the unique challenges posed by working with ionized gases. Furthermore, some setups necessitate advanced configurations—for example, systems designed for magnetic confinement or laser-induced plasma generation—which enhance the versatility of plasma applications and drive forward progress in fields such as research, industrial processing, and energy development.

These sophisticated systems support a diverse range of applications. For example, cold plasma is widely used for surface treatments and atmospheric discharges, while hot plasma is central to fusion energy research. By comprehensively understanding the design and interplay of plasma equipment, scientists and engineers can better manipulate plasma dynamics to meet specific needs. This insight underscores how innovations in equipment design continually enhance the practical and scientific applications of artificial plasma across various domains, thereby generating new opportunities for technological and industrial advancements.

Power supplies provide the energy necessary to ionize the gas and sustain the plasma. The type of power supply used depends on the chosen plasma generation method:

Direct Current (DC) Power Supplies: DC power supplies deliver a constant voltage and are often used in direct current discharge setups. These power sources are essential for ma

Power supplies provide the energy necessary to ionize the gas and sustain the plasma. The type of power supply used depends on the chosen plasma generation method:

Direct Current (DC) Power Supplies: DC power supplies deliver a constant voltage and are often used in direct current discharge setups. These power sources are essential for maintaining stable plasma conditions. For example, high-voltage DC supplies are commonly used in glow discharge tubes, enabling applications that range from surface treatments to analytical techniques in scientific research.

Alternating Current (AC) Power Supplies: Typically used in alternating current discharges at line frequencies (50-60 Hz), AC power supplies are essential for applications such as neon lighting and certain types of plasma-based laboratory equipment. In these applications, AC power enables stable discharges, ensuring consistent illumination and precise plasma generation, thereby enhancing the effectiveness of processes reliant on atmospheric pressure plasmas.

Radio Frequency (RF) Generators: RF generators provide radio frequency power, commonly at 13.56 MHz. They are particularly important in semiconductors, as they facilitate inductively coupled plasma (ICP) systems. Stable RF power levels are crucial for achieving effective plasma generation, enabling uniform processing conditions widely used in etching and deposition processes.

Microwave Sources: Typically generating radiation at a frequency of 2.45 GHz, microwave sources are used in various plasma applications. For example, magnetrons, a type of microwave source, are commonly used in microwave plasma systems to generate plasma for multiple uses, including material processing and surface modification. Their ability to create high-density plasmas makes them valuable for a wide range of industrial applications.

Plasma chambers are essential components in generating artificial plasma as they contain the gas to be ionized and provide a controlled environment for plasma generation. Different types of plasma chambers are designed to meet specific requirements based on the plasma generation method and application. Key types include:

Vacuum Chambers:

Plasma chambers are essential components in generating artificial plasma as they contain the gas to be ionized and provide a controlled environment for plasma generation. Different types of plasma chambers are designed to meet specific requirements based on the plasma generation method and application. Key types include:

Vacuum Chambers: These chambers are designed explicitly for low-pressure plasmas. Typically constructed from durable materials such as stainless steel or glass, vacuum chambers offer both durability and chemical resistance, making them suitable for a wide range of applications. For example, bell jar systems are frequently used in plasma etching applications for microelectronics, where maintaining a low-pressure environment is crucial for achieving high precision and quality.

Atmospheric Pressure Reactors: Designed for plasma generation at ambient pressure, atmospheric pressure reactors offer a simpler and more cost-effective solution compared to vacuum systems. These reactors are versatile and widely used in various applications, including plasma cleaning, activation, and surface treatment. A notable example is the dielectric barrier discharge (DBD) reactor, which effectively produces non-thermal plasmas suitable for various material processing tasks without the complexities associated with vacuum conditions.

Specialized Designs: Certain plasma chambers are designed to accommodate specific plasma types or applications. An example is the Tokamak chambers used in fusion research, which create highly controlled environments necessary for confining hot plasma. These specialized chambers enable researchers to explore advanced plasma dynamics and contribute to future energy solutions through nuclear fusion.

Electrodes and microwave or radio frequency (RF) sources are essential for plasma formation, as they apply electric fields or couple electromagnetic energy into the gas. These components directly influence the efficiency and characteristics of plasma generation. Key aspects include:

Electrode Materials and Configurations: Electrode materi

Electrodes and microwave or radio frequency (RF) sources are essential for plasma formation, as they apply electric fields or couple electromagnetic energy into the gas. These components directly influence the efficiency and characteristics of plasma generation. Key aspects include:

Electrode Materials and Configurations: Electrode materials are crucial for achieving optimal plasma performance and are selected based on their electrical conductivity, thermal stability, and chemical resistance. Common materials include:

Additionally, the shape of electrodes—planar, cylindrical, or pointed—significantly affects electric field distribution and plasma characteristics. For example, pointed electrodes can create stronger electric fields at their tips, facilitating more efficient gas ionization, while planar electrodes can create larger regions of uniform plasma.

RF Antennas for Inductive Coupling: Radio frequency (RF) antennas, including coils or loops, such as helical coil antennas, are used to induce plasma through electromagnetic coupling. These antennas facilitate efficient energy transfer into the gas, generating uniform and stable plasma conditions. This method is widely used in semiconductor processing and material deposition applications, where precise control of plasma characteristics is critical.

Microwave Waveguides and Cavities: Microwave sources require specialized components to direct microwave energy into the plasma. Waveguides and cavities effectively guide the energy, ensuring the plasma receives the necessary power for effective ionization. Devices such as slotted waveguides are commonly implemented in microwave plasma chemical vapor deposition (MP-CVD) systems, where they help achieve uniform plasma coverage over substrates, thereby enhancing material processing efficiency.

Creating and maintaining low-pressure environments is essential for many plasma applications. Proper vacuum systems ensure that gas impurities are minimized, allowing for effective plasma generation. Key components of vacuum systems include:

Vacuum Pumps: Different types of pumps are required to achieve and maintain high vacuum conditions

Creating and maintaining low-pressure environments is essential for many plasma applications. Proper vacuum systems ensure that gas impurities are minimized, allowing for effective plasma generation. Key components of vacuum systems include:

Vacuum Pumps: Different types of pumps are required to achieve and maintain high vacuum conditions. Turbomolecular pumps, often backed by rotary vane pumps, are commonly used for this purpose. These pumps can achieve significantly low pressures by relying on the momentum transfer of gas molecules. In contrast, rotary vane pumps reduce pressure before the turbomolecular pump is engaged initially.

Pressure Gauges: Pressure gauges monitor the pressure inside the plasma chamber. Capacitance manometers are valued for their accuracy, providing precise measurements necessary for effective plasma control. Accurate pressure monitoring enables the optimization of plasma conditions, ensuring that the desired operational parameters are consistently maintained.

Vacuum Fittings and Valves: Vacuum fittings and valves connect and control gas flow within the vacuum system. These components ensure efficient operation by minimizing leaks and enabling precise control of gas delivery. High-quality fittings and valves are essential for maintaining the integrity of the vacuum and ensuring reliable plasma generation.

Gas delivery systems control the flow and composition of gases used to generate plasma. These systems ensure that the right gases are delivered in the correct proportions and conditions for efficient plasma formation. Key components include:

Gas Cylinders and Flow Controllers: Gas cylinders store gases required for plasma generation, while

Gas delivery systems control the flow and composition of gases used to generate plasma. These systems ensure that the right gases are delivered in the correct proportions and conditions for efficient plasma formation. Key components include:

Gas Cylinders and Flow Controllers: Gas cylinders store gases required for plasma generation, while flow controllers regulate the flow of these gases into the plasma chamber. Mass flow controllers (MFCs) are particularly important because they provide precise control over gas mixtures, allowing customized plasma compositions. This accuracy is crucial in applications that require specific chemical reactions and properties.

Pressure Regulators: Pressure regulators maintain the desired gas pressure within the system, ensuring stability and consistency during plasma generation. Proper pressure control is essential for high-purity gas delivery applications, where contaminants can significantly affect plasma behavior and the quality of the resulting materials.

Mixing Systems: Mixing systems combine multiple gases to produce complex plasma chemistries customized for specific applications. For example, gas mixing panels are commonly used in reactive ion etching processes, enabling precise control over the chemical reactions occurring in the plasma. This flexibility allows for the optimization of etching profiles and surface characteristics, which is crucial in semiconductor manufacturing and other advanced material processing applications.

Cooling systems mitigate heat generated during plasma operation. Adequate cooling is essential to prevent overheating of components, ensuring stable plasma generation and prolonging equipment life. Key types of cooling systems include:

Water Cooling for Electrodes and Chambers: Water cooling systems are designed to circulate water around e

Cooling systems mitigate heat generated during plasma operation. Adequate cooling is essential to prevent overheating of components, ensuring stable plasma generation and prolonging equipment life. Key types of cooling systems include:

Water Cooling for Electrodes and Chambers: Water cooling systems are designed to circulate water around electrodes and plasma chambers, effectively dissipating heat. These systems are essential for high-power radio-frequency (RF) plasma sources, where significant heat can be generated. These setups typically utilize chiller systems to maintain optimal operating temperatures, thereby preventing thermal damage and ensuring consistent performance.

Gas Cooling Systems: Gas cooling systems use gas flow to cool components or the plasma. For example, forced air cooling is often applied to atmospheric pressure plasma jets to manage temperature and stabilize plasma conditions. This method can be particularly effective in reducing the thermal load on components, facilitating efficient plasma operations without the complexity of liquid cooling systems.

Monitoring and adjusting plasma parameters are important for effectively operating plasma systems. Various diagnostic tools and control technologies are used to ensure optimal performance and to facilitate precise process management. Key components include:

Optical Emission Spectrometers: These devices analyze the light emitted by the pla

Monitoring and adjusting plasma parameters are important for effectively operating plasma systems. Various diagnostic tools and control technologies are used to ensure optimal performance and to facilitate precise process management. Key components include:

Optical Emission Spectrometers: These devices analyze the light emitted by the plasma, providing valuable information about its composition and state. Optical emission spectrometry enables real-time monitoring of plasma characteristics, allowing operators to make immediate adjustments to optimize processes.

Langmuir Probes: Langmuir probes are used to characterize low-temperature plasmas. They measure parameters such as plasma potential and electron temperature, providing insights into the plasma's electrical properties. This information is important for understanding plasma behavior and optimizing operating conditions.

Mass Spectrometers: Mass spectrometers analyze the composition of plasma species, providing detailed information about the ions and neutral particles present. Quadrupole mass spectrometers are commonly used in reactive plasma environments, allowing for real-time analysis and control of plasma chemistry.

Temperature Sensors: Temperature sensors monitor the temperatures of various components and gases within the plasma system. Accurate temperature measurements are crucial for precise control of plasma processes, which helps prevent thermal damage and ensures reliable operation.

Control Systems and Software integrate and automate plasma operations, enhancing efficiency and reliability. Advanced control software collects and analyzes data in real-time, enabling operators to fine-tune operational parameters and respond quickly to deviations from desired conditions.

Ensuring the safe operation of plasma systems is critical to protect operators and the workplace environment. Various safety measures are implemented to mitigate hazards associated with plasma generation. Key components include:

Radiation Shielding: Radiation shielding is essential for protecting operators from harmful electromagnetic radi

Ensuring the safe operation of plasma systems is critical to protect operators and the workplace environment. Various safety measures are implemented to mitigate hazards associated with plasma generation. Key components include:

Radiation Shielding: Radiation shielding is essential for protecting operators from harmful electromagnetic radiation produced during plasma operation. Faraday cages are commonly used in radio frequency (RF) and microwave plasma systems, providing a conductive enclosure that prevents radiation leakage. This shielding is important for maintaining a safe working environment.

Electrical Safety Interlocks: Electrical safety interlocks are designed to prevent accidental exposure to high voltages during operation. These devices include safety features, such as door interlocks on plasma chamber access panels, which ensure that the system cannot be energized when the access panels are open. This helps significantly reduce the risk of electrical shock or injury.

Gas Detectors and Ventilation Systems: Gas detectors monitor for leaks of hazardous gases within the plasma environment, ensuring that any leaks are promptly identified and addressed. Proper ventilation systems are equally important, particularly in semiconductor processing facilities, as they help to maintain air quality and safety by removing potentially harmful fumes and gases. Together, these systems play a crucial role in workplace safety by mitigating the risks associated with gas exposure.

Certain plasma generation methods require unique equipment customized to specific applications. This specialized equipment is essential for advancing research and facilitating various plasma-related processes. Key examples include:

Laser Systems for Laser-Induced Plasmas: High-power pulsed lasers, such as Nd: YAG (neodymium-doped yttrium

Certain plasma generation methods require unique equipment customized to specific applications. This specialized equipment is essential for advancing research and facilitating various plasma-related processes. Key examples include:

Laser Systems for Laser-Induced Plasmas: High-power pulsed lasers, such as Nd: YAG (neodymium-doped yttrium aluminum garnet) lasers, are utilized for applications like laser-induced breakdown spectroscopy (LIBS). In LIBS, a high-intensity laser pulse interacts with a material, creating a plasma plume that can be analyzed to determine the target's elemental composition. This technique is widely used in material science, environmental monitoring, and forensics fields.

Shock Tubes for Shock Wave Ionization: Shock tubes are specialized systems designed to generate strong shock waves. They are used to create and study plasmas under controlled conditions. Diaphragm-type shock tubes are particularly favored in hypersonic plasma research, where they facilitate the simulation of high-speed flows and ionization phenomena. These systems allow researchers to investigate the behavior of plasmas in extreme environments, contributing valuable knowledge to aerospace and propulsion studies.

Magnetic Field Coils and Permanent Magnets: Magnetic field coils and permanent magnets are essential for shaping and confining plasmas. Helmholtz coils, for example, create uniform magnetic fields crucial for various plasma research applications, including magnetic confinement fusion. These devices enable precise control over plasma stability and behavior, supporting experimental investigations into plasma properties and dynamics.

A plasma reactor is a complex system designed to generate, sustain, and regulate plasma, a distinct state of matter characterized by its electrical conductivity and responsiveness to electromagnetic fields. These unique properties make plasma highly valuable for various applications across industries, including manufacturing, environmental management, and advanced scientific research in fields such as physics, chemistry, and engineering.

The design and configuration of artificial plasma reactors are critical in determining their efficiency and performance in plasma generation. Key components, including electrodes, dielectric layers, discharge gaps (also known as plasma gaps), and plasma discharge, are crucial in the reactor's operation. Each of these elements interacts to create a stable and controlled plasma environment engineered to the specific requirements of the application, whether it involves material processing, waste treatment, or experimental research. A thorough understanding of how these components function and influence plasma behavior is essential for optimizing the reactor's performance and achieving desired outcomes.

Producing artificial plasma depends on specialized equipment and the proper integration of these core components within the reactor. Effective system design and seamless interaction between the different elements are essential for reliable operation, efficient plasma generation, and adaptability to various applications. This integration highlights the importance of technical precision and a profound understanding of plasma science in maximizing the potential of plasma reactors.

Electrodes are the conductive surfaces within a plasma reactor that enable the flow of electrical current, facilitating the generation and sustainment of plasma. They play a critical role in creating and maintaining the plasma state, which is essential for the reactor's operation.

Purpose: The primary function of the electrodes is to init

Electrodes are the conductive surfaces within a plasma reactor that enable the flow of electrical current, facilitating the generation and sustainment of plasma. They play a critical role in creating and maintaining the plasma state, which is essential for the reactor's operation.

Purpose: The primary function of the electrodes is to initiate and sustain plasma by facilitating the gas ionization within the reactor. When a sufficient voltage is applied across the electrodes, energy is transferred to the gas molecules, causing their ionization and the formation of plasma. This ionized state consists of free electrons and positively charged ions, which can be manipulated for various applications, such as material processing, surface modification, and chemical synthesis. By effectively controlling the energy input and the characteristics of the electric field between the electrodes, the plasma can be customized to meet specific operational requirements.

Importance: The effectiveness of a plasma reactor heavily relies on the design and material of its electrodes. The physical and electrical properties of the electrodes significantly influence the efficacy of plasma generation, affecting parameters such as power consumption, ionization rate, and overall reactor stability. A well-designed electrode system can optimize these parameters, improving performance and efficiency. For example, the choice of material can enhance both electrical conductivity and thermal stability, while the geometric arrangement of the electrodes can influence the uniformity of the plasma. By focusing on these design aspects, scientists and engineers can achieve a more stable and effective plasma state customized to meet specific operational requirements.

Materials: The choice of electrode material directly impacts several critical operating conditions, including electrical conductivity, thermal stability, and chemical reactivity. Common materials used for electrodes include:

Configurations: Electrodes can be arranged in various geometries, such as parallel plates, rods, or coils. The choice of configuration affects the electric field distribution and the characteristics of the resulting plasma. The specific arrangement of electrodes is customized to align with the plasma reactor's intended applications, optimizing performance for each unique process. By selecting the appropriate configuration, scientists and engineers can significantly influence key factors such as plasma stability, efficiency, and overall reactor performance.

Voltage and Frequency: The design and configuration of the electrodes influence the voltage and frequency applied in the reactor.

Gas Composition: The interaction between the electrodes and the gas in the plasma gap can significantly influence discharge behavior.

The dielectric layer, or dielectric barrier, is an insulating material placed between or on one or more of the electrodes in a plasma reactor. This layer facilitates the generation and maintenance of plasma while preventing unwanted electrical discharge, such as arcs or sparks.

Purpose: The dielectric layer's primary function is to preven

The dielectric layer, or dielectric barrier, is an insulating material placed between or on one or more of the electrodes in a plasma reactor. This layer facilitates the generation and maintenance of plasma while preventing unwanted electrical discharge, such as arcs or sparks.

Purpose: The dielectric layer's primary function is to prevent direct electrical discharge between the electrodes. This separation is crucial for creating and maintaining stable, controlled plasma conditions, which are essential for many applications that require precise control over plasma properties.

Importance: A well-designed dielectric layer is essential for ensuring plasma stability and optimizing discharge characteristics. It contributes to efficient plasma generation by maintaining the necessary electric field while minimizing energy losses and preventing arcing or short circuits within the reactor. By effectively managing the electric field configuration, the dielectric layer enhances the overall efficiency of the plasma generation process and promotes operational reliability. This stability is essential for achieving consistent plasma properties and is crucial for applications such as material processing, environmental remediation, and advanced research.

Materials: The choice of materials for the dielectric layer is influenced by several factors, including the dielectric constant, chemical resistance, and thermal stability. Common materials used for dielectric layers include:

Voltage and Discharge Control: The properties of the dielectric layer significantly influence the voltage threshold necessary for discharge.

Temperature Effects: The thermal stability of the dielectric layer affects its performance under various operational conditions.

Dielectric Breakdown: Dielectric breakdown refers to the failure of an insulating material (dielectric layer) to resist electrical conduction, which causes a sudden increase in current flow through the dielectric layer.

The discharge gap, or plasma gap, is the space between the electrodes in a plasma reactor. It is filled with gas that becomes ionized, forming plasma. This gap is crucial for plasma formation and stability, and it affects various operational parameters within the reactor.

Purpose: The primary purpose of the plasma gap is to establish the

The discharge gap, or plasma gap, is the space between the electrodes in a plasma reactor. It is filled with gas that becomes ionized, forming plasma. This gap is crucial for plasma formation and stability, and it affects various operational parameters within the reactor.

Purpose: The primary purpose of the plasma gap is to establish the electric field necessary for ionizing the gas. The dimensions of this gap are essential for determining the strength of the electric field applied, which directly impacts the efficiency of plasma generation. A well-defined plasma gap allows effective ionization control, ensuring optimal gas conversion into plasma.

Importance: The size and shape of the plasma gap significantly influence several key discharge characteristics:

Size Considerations: Plasma gaps can vary widely, typically ranging from a few millimeters to several centimeters, depending on several factors:

Gas Composition and Pressure Effects: The properties of the plasma gap, including gas composition and pressure conditions, significantly influence discharge behavior.

Operational Parameters: Achieving an optimal balance between plasma gap size and other operational parameters is essential.

Plasma discharge refers to the flow of electrical current through the gas or air gap (plasma gap) between the electrodes, facilitated by the dielectric barrier.

Importance: This flow results in the ionization of the gas, creating plasma without leading to a continuous arc or spark. Controlled discharge is crucial for applications that requ

Plasma discharge refers to the flow of electrical current through the gas or air gap (plasma gap) between the electrodes, facilitated by the dielectric barrier.

Importance: This flow results in the ionization of the gas, creating plasma without leading to a continuous arc or spark. Controlled discharge is crucial for applications that require a stable plasma, such as chemical reactions, sterilization processes, or surface treatments, where uniformity and reliability are paramount. By managing discharge effectively, operators can ensure consistent plasma characteristics, which are important for optimizing results in these applications.

Key Factors Affecting Discharge:

.

Plasma generation is governed by a complex interplay of factors that significantly influence its properties, stability, and applications. Understanding these factors is essential for optimizing plasma behavior and engineering its characteristics for specific industrial and research purposes. From the composition of the gas to the design of electrode configurations, each parameter directly impacts essential plasma properties, such as density, energy distribution, and stability. By exploring the key factors—gas composition, pressure, temperature, power input, electrode configuration, magnetic fields, frequency of energy input, and gas flow rates—we can better appreciate the fundamental mechanisms driving plasma generation and how they can be optimized for advanced technologies such as semiconductor manufacturing, fusion research, materials processing, medical therapies, and environmental remediation.

Plasma generation and its properties are highly sensitive to various factors, each of which requires careful consideration for precise control. Gas composition, pressure, temperature, power input, electrode configuration, magnetic fields, and gas flow rates collectively determine the stability, density, and energy dynamics of the plasma. Understanding and precisely controlling these factors enables innovations across diverse applications, from improving plasma-based manufacturing processes to advancing research in fusion energy. By maintaining optimal conditions and leveraging insights into the interactions of these factors, scientists and engineers can achieve unprecedented precision and efficiency in harnessing the power of plasmas for various technological advancements.

The type of gas used in plasma generation has a significant impact on the formation and characteristics of the plasma. Key aspects of gas composition include:

Ionization Potential: Different gases exhibit varying ionization potentials, which affect how readily they can be ionized. Noble gases, such as argon, have lower ionization potentia

The type of gas used in plasma generation has a significant impact on the formation and characteristics of the plasma. Key aspects of gas composition include:

Ionization Potential: Different gases exhibit varying ionization potentials, which affect how readily they can be ionized. Noble gases, such as argon, have lower ionization potentials, making them easier to ionize.

Electron Attachment: Electronegative gases (e.g., oxygen, chlorine) can capture free-flowing electrons, affecting plasma stability and electron density. This electron attachment can alter the overall plasma behavior and performance.

Molecular vs. Atomic Gases: Molecular gases contain additional energy states (rotational, vibrational) that absorb energy differently than atomic gases. This distinction affects the energy distribution and dynamics within the plasma, influencing its properties and potential applications.

Pressure, defined as the force exerted per unit area on a surface, significantly affects plasma behaviors. Key aspects include:

Mean Free Path: At lower pressures, the mean free path—the average distance a particle travels before colliding with another particle—is longer. This allows electrons to gain more energy between collisions, enhan

Pressure, defined as the force exerted per unit area on a surface, significantly affects plasma behaviors. Key aspects include:

Mean Free Path: At lower pressures, the mean free path—the average distance a particle travels before colliding with another particle—is longer. This allows electrons to gain more energy between collisions, enhancing ionization efficiency and energy transfer within the plasma.

Collision Frequency: Higher pressure increases particle density, resulting in a higher collision frequency. Frequent collisions can impact plasma stability, potentially leading to instabilities or energy losses and influencing overall plasma behavior and performance.

Plasma Confinement: Lower pressure correlates with lower particle density and collisional frequency, improving plasma confinement. Effective confinement is crucial for applications such as fusion research and plasma processing technologies.

The temperature of the gas used or the surrounding environment has a significant influence on plasma generation and its associated properties. Key aspects include:

Gas Temperature: The temperature of the gas affects the kinetic energy of its particles, influencing ionization efficiency. Higher gas temperatures lead to increased molecular

The temperature of the gas used or the surrounding environment has a significant influence on plasma generation and its associated properties. Key aspects include:

Gas Temperature: The temperature of the gas affects the kinetic energy of its particles, influencing ionization efficiency. Higher gas temperatures lead to increased molecular motion, enhancing the likelihood of ionization and resulting in a more robust plasma. Additionally, increased temperatures can result in a longer mean free path, allowing electrons to gain more energy between collisions, further enhancing ionization efficiency.

Molecular Reactions: The reactivity of a gas is affected by its temperature, particularly in molecular gases, where higher temperatures activate additional energy states, including vibrational and rotational states. This increased reactivity can significantly impact the plasma's characteristics and behavior.

Environmental Temperature: The overall ambient temperature influences plasma stability, energy retention, and containment efficiency. A warmer environment reduces thermal losses, promoting more efficient plasma generation, while extreme cold can lead to increased energy losses and instability.

Material Properties: The ambient temperature can also affect the physical properties of materials used in the plasma generation system, impacting their conductivity and durability under high-temperature conditions.

Temperature Control: Maintaining optimal gas and environmental temperatures is crucial for precise plasma applications, such as semiconductor manufacturing, where temperature fluctuations can significantly impact product quality.

The energy supplied to the plasma system—whether thermal energy, electric power, or electromagnetic radiation—significantly influences plasma properties:

Degree of Ionization: Higher power inputs typically result in increased ionization, leading to a more energetic plasma due to a higher concentration of charged particles.

Plasma Density

The energy supplied to the plasma system—whether thermal energy, electric power, or electromagnetic radiation—significantly influences plasma properties:

Degree of Ionization: Higher power inputs typically result in increased ionization, leading to a more energetic plasma due to a higher concentration of charged particles.

Plasma Density: Plasma density, defined as the number of charged particles (ions and electrons) per unit volume, is directly correlated with the power input. Greater power typically increases plasma density, enhancing its overall behavior.

Plasma Temperature: The power input has a direct impact on the plasma temperature, particularly the electron temperature in non-equilibrium plasmas. In these plasmas, electrons can reach much higher temperatures than the ions, resulting in a non-uniform energy distribution among species.

The design and arrangement of electrodes in plasma generation systems play an essential role in determining electric field dynamics, secondary electron emission, and plasma-surface interactions:

Electric Field Distribution: The shape and placement of electrodes are crucial for establishing a uniform electric field. A well-designed system

The design and arrangement of electrodes in plasma generation systems play an essential role in determining electric field dynamics, secondary electron emission, and plasma-surface interactions:

Electric Field Distribution: The shape and placement of electrodes are crucial for establishing a uniform electric field. A well-designed system ensures consistent plasma formation.

Secondary Electron Emission: High-energy electrons colliding with electrode surfaces can emit additional electrons, which are essential for maintaining electrical discharges. The electrode material has a significant impact on this phenomenon, affecting overall efficiency.

Plasma-Surface Interactions: The geometric configuration of the electrodes, along with the composition of both the electrodes and the surface materials, significantly impacts the interactions between plasma and surfaces. These interactions are crucial in processes such as sputtering, where material is ejected from a surface due to ion bombardment, and deposition, where material is applied to a surface from the plasma. The shape of the electrodes and the materials used can dramatically impact the quality of the produced materials.

Applied magnetic fields significantly enhance plasma generation and control, especially in applications ranging from materials processing to fusion research. Key functions include:

Plasma Confinement: Magnetic fields effectively confine charged particles within a plasma, significantly increasing plasma density and stability. This confinem

Applied magnetic fields significantly enhance plasma generation and control, especially in applications ranging from materials processing to fusion research. Key functions include:

Plasma Confinement: Magnetic fields effectively confine charged particles within a plasma, significantly increasing plasma density and stability. This confinement is essential for maintaining the required conditions for various applications.

Electron Cyclotron Resonance: In microwave plasma sources, magnetic fields facilitate electron cyclotron resonance, where the frequency of microwave radiation matches the natural frequency of the electrons in the magnetic field. This resonance enhances ionization efficiency by generating more charged particles, resulting in more effective plasma.

Plasma Shaping and Direction: Magnetic fields can control the shape and direction of plasma streams, which is crucial in applications like plasma thrusters used in spacecraft propulsion. Optimizing plasma geometry and flow can improve operational performance.

The frequency at which energy is input into the plasma system greatly influences its stability and ionization characteristics. Different frequencies can result in varying coupling efficiencies with the plasma, influencing energy absorption and utilization during the ionization process.

Resonance Effects: Certain frequencies may resonate w

The frequency at which energy is input into the plasma system greatly influences its stability and ionization characteristics. Different frequencies can result in varying coupling efficiencies with the plasma, influencing energy absorption and utilization during the ionization process.

Resonance Effects: Certain frequencies may resonate with electron motion, leading to more efficient energy absorption and increased ionization rates. In contrast, other frequencies may not couple effectively with the plasma, resulting in lower ionization and less stable conditions.

The rate at which gas is introduced into the plasma system affects the density and uniformity of the plasma:

Gas Mixing: The flow rate also affects the mixing of different gases, which can be crucial for applications that require specific chemical compositions in the plasma.

Stability and Control: Optimal gas flow rates help maintain plas

The rate at which gas is introduced into the plasma system affects the density and uniformity of the plasma:

Gas Mixing: The flow rate also affects the mixing of different gases, which can be crucial for applications that require specific chemical compositions in the plasma.

Stability and Control: Optimal gas flow rates help maintain plasma stability and enable precise control over plasma properties, essential for various industrial and research applications.

Artificial plasma holds enormous potential for transforming various industries, including manufacturing, healthcare, and environmental management. However, harnessing and maintaining stable, efficient, and uniform plasma often involves overcoming significant challenges. These challenges arise from the inherent complexities of plasma science, operational conditions, scalability requirements, and material constraints. Addressing these issues is crucial to optimizing plasma-based technologies and unlocking their full potential across diverse applications. Some of the key challenges associated with plasma generation and control include:

Advancing artificial plasma technology requires a robust understanding of its inherent challenges and strategic efforts to address them. From ensuring stability under various pressure conditions to optimizing material durability, energy efficiency, and scalability, overcoming these obstacles will enable plasma-based solutions to achieve their full potential. As industries seek to innovate and improve performance, investments in research and development are crucial for harnessing the capabilities of plasma technology across various applications, including industrial manufacturing, environmental remediation, and healthcare. With continued progress, plasma science will undoubtedly play a crucial role in driving technological advancements and sustainability in the coming decades.

Atmospheric pressure presents unique challenges for controlling plasma instabilities, significantly impacting plasma performance and application outcomes. Key challenges include:

Glow-to-Arc Transition: Glow discharges are low-current electrical discharges that produce uniform, glowing plasma, while arc discharges are high-current, lumino

Atmospheric pressure presents unique challenges for controlling plasma instabilities, significantly impacting plasma performance and application outcomes. Key challenges include:

Glow-to-Arc Transition: Glow discharges are low-current electrical discharges that produce uniform, glowing plasma, while arc discharges are high-current, luminous, and thermal states. At atmospheric pressure, glow discharges can unexpectedly transition into arc discharges. This transition results in increased temperatures and reduced control over plasma conditions, leading to unwanted heating and material degradation. Such instability can complicate processes that require precisely controlled plasma characteristics.

Filamentation: Filamentation refers to the formation of thin, thread-like structures within the plasma, rather than a consistent, uniform discharge. Under atmospheric pressure (high pressure), plasmas tend to develop filamentary structures, which create inconsistencies in plasma behavior. This phenomenon poses challenges for applications that depend on stable plasma characteristics, as it can lead to hotspots and uneven material treatment, detracting from the efficacy of processes such as etching or coating.

Fast Timescales: The ionization processes that convert atoms or molecules into ions and free-flowing electrons occur rapidly, especially at atmospheric pressure. The rapid generation of charged species necessitates swift control mechanisms to maintain plasma stability. Effective plasma management is crucial for industrial and research applications to prevent fluctuations that could compromise performance and reliability, especially in sensitive processes.

Pressure-Dependent Instabilities: Plasma instabilities, such as ionization waves and striations, can disrupt the smooth operation needed for effective plasma applications. These instabilities are particularly pronounced in molecular and electronegative gases, where electrons may be trapped and released. The underlying mechanisms of these instabilities are not fully understood, which complicates efforts to maintain stable plasma conditions and limits practical applications in many fields.

In non-atmospheric, typically low-pressure, environments, controlling plasma instabilities presents additional challenges, including:

Sheath Instabilities: The plasma sheath is a boundary layer near surfaces within the plasma, regulating the flow of charged particles through an electric field. At low pressure, instabilities in these sheat

In non-atmospheric, typically low-pressure, environments, controlling plasma instabilities presents additional challenges, including:

Sheath Instabilities: The plasma sheath is a boundary layer near surfaces within the plasma, regulating the flow of charged particles through an electric field. At low pressure, instabilities in these sheath regions can adversely affect plasma uniformity and stability. This is particularly important for applications such as semiconductor manufacturing and surface treatment, where precise control over plasma properties is crucial for achieving the desired outcomes.

Wave-Particle Interactions: Plasma waves involve oscillating electric and magnetic fields that interact with charged particles in the plasma. These interactions can lead to instabilities that disrupt plasma generation and maintenance. Understanding these wave-particle interactions is essential for optimizing reactor designs and operational protocols to ensure consistent and effective plasma behavior.

Drift Instabilities: Drift instabilities occur in magnetized plasmas subjected to external magnetic fields. Variations in plasma density or temperature gradients can lead to these instabilities, complicating efforts to control the plasma properties. This unpredictability can adversely affect applications that depend on reliable and consistent plasma behavior.

Pressure-Dependent Collision Frequencies: Collision frequencies determine the frequency at which particles within the plasma collide. Changes in pressure alter the balance among different collision types—such as electron-neutral, ion-neutral, and Coulomb interactions—influencing plasma stability and behavior. At lower pressures, mean free paths—the average distance a particle travels between collisions—increase, potentially enhancing certain instabilities and complicating plasma control.

Due to the harsh conditions created during plasma generation, the materials used in plasma reactors face significant challenges. These challenges include erosion, thermal fatigue, and chemical reactions with the plasma, all of which can impact the performance and lifespan of reactor components, resulting in increased maintenance and repla

Due to the harsh conditions created during plasma generation, the materials used in plasma reactors face significant challenges. These challenges include erosion, thermal fatigue, and chemical reactions with the plasma, all of which can impact the performance and lifespan of reactor components, resulting in increased maintenance and replacement costs.

Erosion: Plasma environments can cause substantial erosion of reactor materials, particularly when high-energy ions and electrons bombard surfaces. Over time, this erosion can degrade key components, compromising the reactor's performance and requiring frequent maintenance or replacement.

Thermal Fatigue: Plasma generation often involves rapid temperature fluctuations, which can lead to thermal stresses in reactor materials. If not adequately managed, these temperature changes can result in material fatigue, weakening components, and potentially lead to catastrophic failures.

Chemical Reactions: The plasma's high reactivity can lead to chemical interactions with reactor materials. For example, corrosive species produced during plasma processes can degrade materials more rapidly than anticipated, thereby affecting the reactor's integrity and reliability.

Longevity and Consistency: The choice of materials has a significant impact on the longevity and consistency of reactor components and plasma generation. Durable materials that can withstand erosion, thermal stress, and chemical attack are essential for maintaining reliable operational conditions. Inadequate material selection can lead to variations in plasma characteristics, resulting in inconsistent process outcomes.

Cost Considerations: While selecting high-performance materials may involve higher initial costs, these materials can ultimately result in lower long-term maintenance and replacement costs. Therefore, balancing material costs with performance and durability is essential for optimizing reactor design and operation.

Effective shielding, which involves using materials and structures to block harmful radiation and charged particles, and containment, defined as methods to securely trap plasma within a designed area, are essential for managing plasma environments. These strategies ensure the safety of personnel and equipment while maintaining energy effi

Effective shielding, which involves using materials and structures to block harmful radiation and charged particles, and containment, defined as methods to securely trap plasma within a designed area, are essential for managing plasma environments. These strategies ensure the safety of personnel and equipment while maintaining energy efficiency. Key aspects of this challenge include:

Radiation Protection: Plasma generation produces various forms of radiation, including ultraviolet (UV), X-rays, and other forms of ionizing radiation. Effective shielding is necessary to protect personnel and sensitive equipment from exposure to harmful radiation, which can pose serious health risks and damage electronic components.

Heat Management: The high temperatures generated during plasma processes can cause heat radiation that may affect adjacent materials and systems. Proper containment strategies must be implemented to mitigate heat transfer and ensure the surrounding equipment remains operational and safe.

Containment of Charged Particles: Charged particles, including ions and electrons, can escape the plasma region if they are not adequately contained. Efficient containment systems must be designed to capture these particles while minimizing losses that can reduce the overall efficiency of the plasma process.

Balancing Containment and Energy Transfer: Maintaining effective shielding while allowing efficient energy transfer to the plasma is a complex and challenging task. Optimal designs must ensure that the plasma remains contained without impeding the necessary energy input that drives the ionization and sustains the plasma state.

Environmental Hazards and Safety Concerns: Inadequate shielding can lead to environmental hazards, including the release of toxic or reactive species into the atmosphere. Safety protocols and effective containment measures are crucial for preventing potential accidents and ensuring regulatory compliance.

Energy Losses: Inefficient shielding can result in significant energy losses during plasma processing, ultimately increasing operational costs. Strategies to improve energy efficiency include optimizing the design of containment systems to minimize leakage and maximize energy transfer to the plasma.

The ability to control plasma chemistry is crucial for applications such as etching, deposition, and materials synthesis. Gas mixtures, flow rates, and pressure variations can lead to unpredictable results. Inconsistent plasma chemistry can compromise product quality and yield, particularly in sensitive applications such as semiconductor

The ability to control plasma chemistry is crucial for applications such as etching, deposition, and materials synthesis. Gas mixtures, flow rates, and pressure variations can lead to unpredictable results. Inconsistent plasma chemistry can compromise product quality and yield, particularly in sensitive applications such as semiconductor fabrication or biomedical processes.

Variations in Gas Mixtures: The composition of the gas mixture used in plasma generation significantly affects the chemical reactions that occur within the plasma. Variations in gas ratios can lead to unpredictable outcomes, impacting the desired properties of the final products. Achieving the right balance of precursor materials is crucial for consistent results.

Flow Rates: The flow rates of gases entering the plasma reactor must be carefully regulated. Changes in flow rates can alter the density and dynamics of the plasma, leading to variations in the chemical environment. This can directly affect the efficiency of processes such as etching and coating, where uniformity is critical.

Pressure Control: Plasma behavior is highly sensitive to pressure variations. Inconsistent pressure levels can lead to fluctuations in ionization rates, electron density, and overall plasma stability. Tight pressure control ensures predictable plasma chemistry and reliable process outcomes.

Inconsistent Plasma Chemistry: Variations in gas mixtures, flow rates, or pressure can lead to inconsistent plasma chemistry. This unpredictability can compromise product quality and yield, particularly in sensitive applications such as semiconductor fabrication or biomedical processes, where precise chemical control is crucial.

Impact on Product Quality: Inconsistent plasma chemistry can lead to defects, non-uniform coatings, ineffective etching, and oxidation, ultimately affecting the performance and reliability of the final products. In the electronics, healthcare, and agriculture industries, the repercussions of poor plasma control can be substantial, resulting in increased waste and higher production costs.

Electromagnetic interference (EMI) can significantly impact plasma systems and nearby equipment, particularly those utilizing high-frequency power supplies or radio frequency (RF) generators. EMI can lead to measurement errors and control issues, necessitating the use of additional shielding or filtering to maintain the integrity of diagn

Electromagnetic interference (EMI) can significantly impact plasma systems and nearby equipment, particularly those utilizing high-frequency power supplies or radio frequency (RF) generators. EMI can lead to measurement errors and control issues, necessitating the use of additional shielding or filtering to maintain the integrity of diagnostics and control systems.

Generation of EMI: High-frequency power supplies and RF generators used in plasma generation can emit electromagnetic radiation that interferes with the operation of nearby electronic equipment. This interference can disrupt the normal functioning of sensors, diagnostic tools, and control systems, leading to erratic readings and compromised performance.

Measurement Errors: EMI can cause measurement errors in various diagnostic equipment that monitors plasma conditions. Inaccurate readings can hinder plasma stability and performance assessment, complicating process control and optimization.

Control Issues: EMI can lead to control problems in plasma systems, where precise regulation of parameters such as plasma power, flow rates, and pressure is necessary. Interference may affect the responsiveness of control systems, making it challenging to maintain desired operating conditions.

Need for Additional Shielding or Filtering: Plasma systems often require additional shielding or filtering solutions to mitigate the effects of electromagnetic interference (EMI). Effective shielding can help contain electromagnetic radiation, while filtering mechanisms can reduce the impact of interference on sensitive electronics.

Impact on System Integrity: Without proper measures to address EMI, the integrity of diagnostics and control systems can be compromised, potentially leading to inefficiencies, increased downtime, and reduced product quality. Ensuring the reliability of these systems is essential for the successful operation of plasma technologies.

Scaling plasma processes from laboratory settings to industrial production introduces new complexities. Maintaining reproducibility in plasma properties and behavior can be difficult as systems scale. Inconsistent performance during scaling can lead to product variability and inefficiencies in production processes, resulting in costly and

Scaling plasma processes from laboratory settings to industrial production introduces new complexities. Maintaining reproducibility in plasma properties and behavior can be difficult as systems scale. Inconsistent performance during scaling can lead to product variability and inefficiencies in production processes, resulting in costly and detrimental effects on quality standards.

Complex Transition from Laboratory to Industrial Scale: The conditions and parameters that work effectively in small-scale laboratory experiments may not directly translate to larger industrial systems. System geometry, gas flow dynamics, and plasma uniformity can vary significantly at scale, necessitating careful consideration during the design and implementation phases.

Maintaining Reproducibility: As systems are scaled up, achieving reproducible plasma properties and behavior becomes increasingly complex. Variations in material properties, environmental conditions, and processing parameters can all affect plasma characteristics, resulting in inconsistencies between batches.

Product Variability: Inconsistent plasma behavior during scaling can lead to product variability, which affects the quality and performance of the final products. For industries such as semiconductor manufacturing and coatings, where precision is crucial, even minor fluctuations in plasma conditions can result in significant deviations in product quality.

Inefficiencies in Production Processes: Plasma processes lacking reproducibility can lead to inefficiencies in production. Unpredictable outcomes may necessitate additional steps in quality control, resulting in increased waste and ultimately leading to higher production costs, which can compromise overall efficiency.

Cost Implications: The challenges associated with scaling and reproducibility can have profound financial implications. Increased variability and inefficiencies lead to higher operational costs, which in turn affect profitability and market competitiveness.

The energy-intensive nature of plasma generation presents significant challenges to its economic viability and sustainability. Balancing energy input with plasma performance remains a constant challenge. High operational costs can limit the adoption of plasma technologies, particularly in resource-sensitive industries, while improving ene

The energy-intensive nature of plasma generation presents significant challenges to its economic viability and sustainability. Balancing energy input with plasma performance remains a constant challenge. High operational costs can limit the adoption of plasma technologies, particularly in resource-sensitive industries, while improving energy efficiency can lead to more sustainable and economically feasible processes.

Energy Optimization: Optimizing energy use in plasma generation is essential for cost-effectiveness. Efficient energy management strategies must be developed to balance the energy input against plasma performance, minimizing waste while maximizing productivity.

High Operational Costs: Operating plasma systems can be costly, particularly in terms of energy consumption. These costs may deter the adoption of plasma technologies, especially in resource-sensitive industries such as manufacturing, where budget constraints are significant.

Balancing Input and Performance: Achieving a balance between energy input and plasma performance is an ongoing challenge. Factors such as power supply efficiency, gas flow rates, and reactor design all influence how effectively energy is used to sustain desired plasma characteristics.

Sustainable Processes: Improving energy efficiency contributes to more sustainable plasma processes. By reducing energy consumption, companies can decrease their carbon footprint and operate more environmentally friendly, aligning with global sustainability goals.

Economic Feasibility: The financial feasibility of plasma technologies is directly tied to energy efficiency. Processes that can operate effectively with lower energy inputs are more likely to be adopted across various industries. Enhancing energy efficiency can also improve market competitiveness.

Innovation and Investment: Addressing energy efficiency issues often requires investment in innovative technologies and techniques. Research into advanced power supply designs, new reactor configurations, and enhanced process monitoring can yield substantial improvements in energy performance.